Our Construction Systems for all needs

Description and Construction Systems Applied by Prometeus SRL

Prometeus Srl is able to satisfy every type of need depending on the project that the customer wants to tackle. The construction systems we propose are made with the best wood materials on the market and are suitable for any type of atmospheric element. The construction system is also gradually evaluated according to the area where it is to be built and according to the economic possibilities of the customer. Below we have described the current construction techniques adopted by our company.

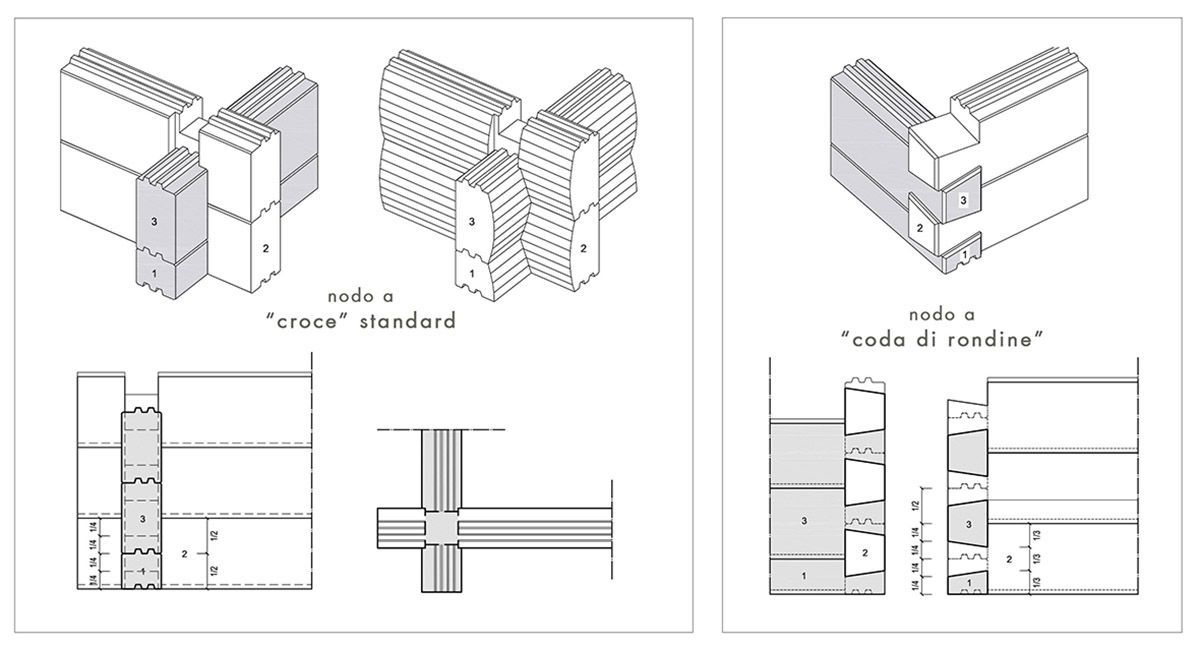

Block House Construction System

the technique involves the overlapping of trunks, one on top of the other, in height, raising the wall until it joins it with the roof.

The joint is made in the corners, through recesses between the boards which give rigidity to the structure.

- “cross” knot (standard) “dovetail” knot

Through modern CNC machines (Control Numeric Number or Numerical Control Machines) we are able to create elaborate and precise carvings in the wood allowing very advanced and refined interlocking systems.

The trunks shaped into shape and milled on both faces are placed in contact with each other obtaining guides which favor the stability of the pieces.

The corner knots have more accurate and varied finishes for safety. Furthermore, holes are drilled every certain distance to allow the insertion of steel bars which anchor the structure to the ground, preventing it from overturning in the event of earthquakes.

CONSTRUCTION SECTIONS AND THEIR USE

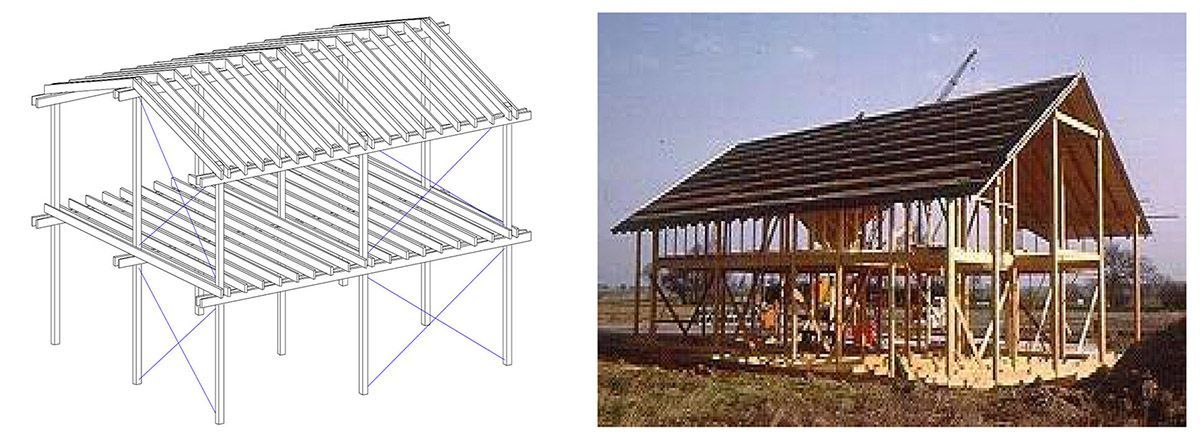

Frame Construction System.

Wooden frame structures are made with solid or laminated wood beams that act as beams or pillars.

A very ancient technique, which from a static point of view is the transposition of the "trilithic" system: two vertical uprights, surmounted by a horizontal rod (portal).

The system, also called load-bearing frame or cage, allows great flexibility and versatility of use.

Beams and pillars perform the load-bearing function of the structure, leaving large free open spaces, which can be infilled at will with arbitrary shapes and materials, as they only have a stiffening function.

Of fundamental importance are the bracing elements, which absorb and counteract the horizontal thrusts of wind and earthquakes, stabilizing the building.

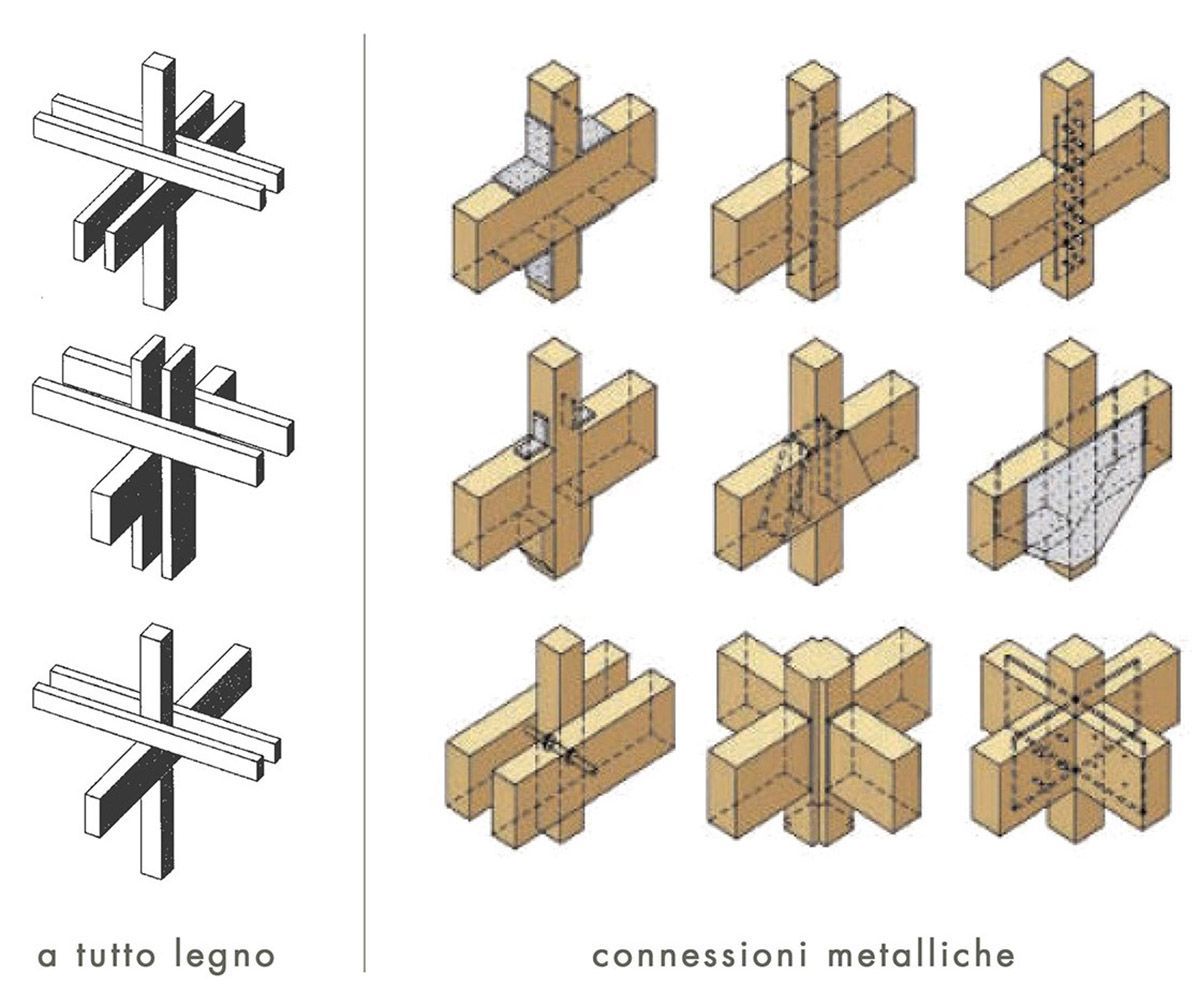

Of fundamental importance are the techniques and types of joints of the various elements constituting the load-bearing framework of the building.

The wooden elements can be joined together through connections:

- all woodmetallic

The law requires the use of metal connectors, although ancient Chinese architecture and Japanese pagodas are prestigious witnesses of how wood, if properly worked, is self-sufficient.

CONSTRUCTION SECTIONS AND THEIR USE

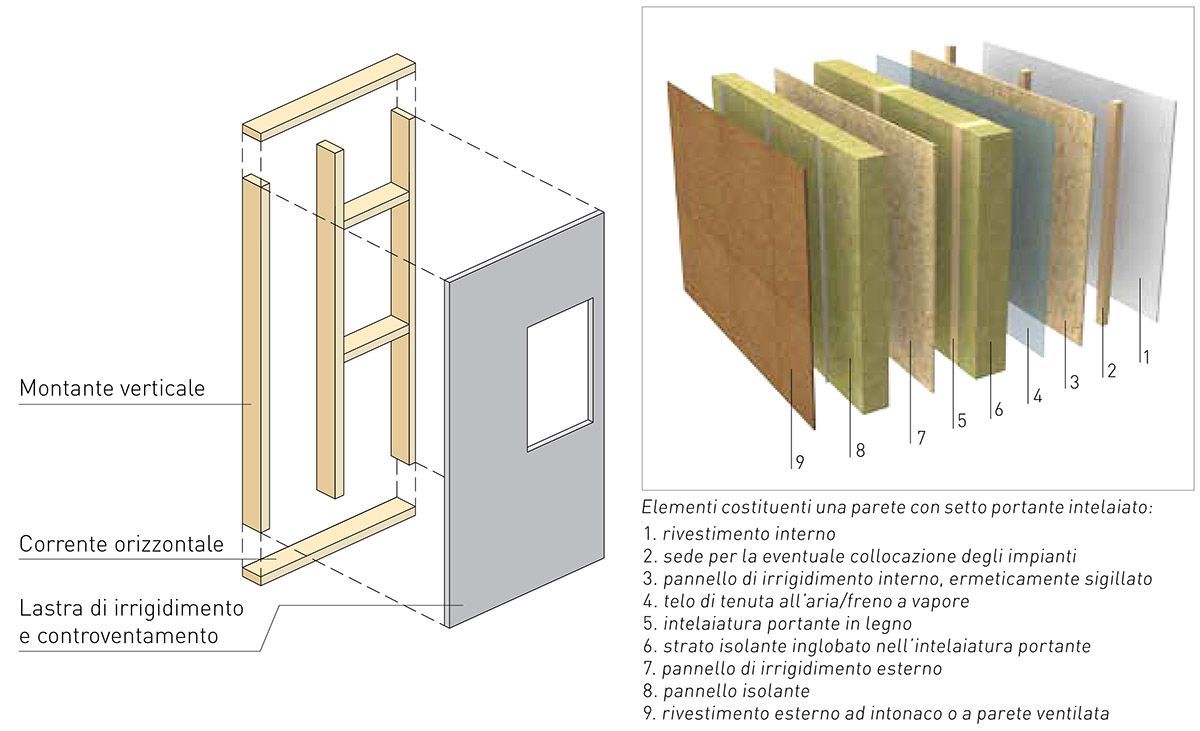

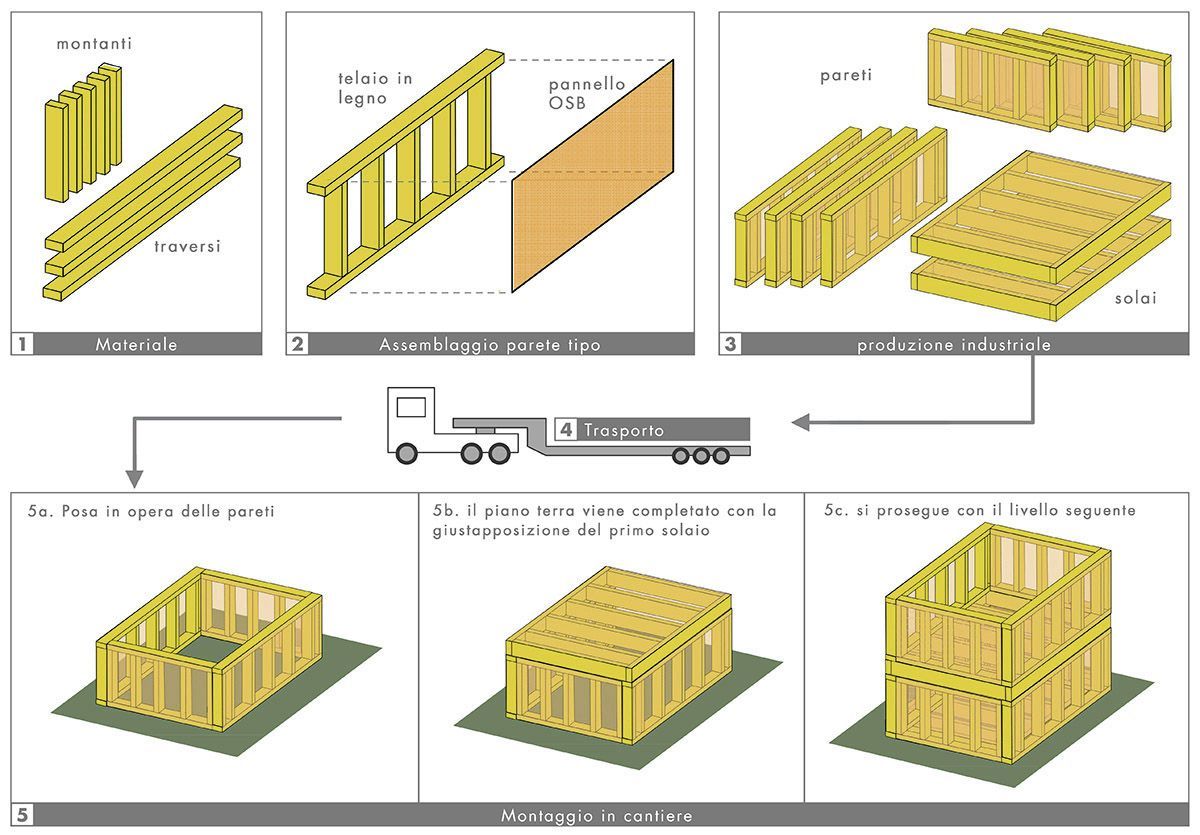

Platform frame construction system: the framed structure

The Platform Frame is, in its basic unit, a frame composed of wooden elements of small section (5×10 mm, 4×9 mm) which, depending on their position, are called uprights (vertical) and joists ( horizontal).

This skeleton is then closed by means of nailed or screwed wooden panels (usually OSB, plywood or 45° boards).

The great advantage, in addition to the lightness and ease of installation, is the possibility of integrating the insulating layer or insulation within its thickness, in the spaces between the joists.

The Platform Frame is a lightweight construction method that can be built directly on site or

pre-assembled in the factory including fixtures and insulation, to then be quickly installed by placing the walls together and overlapping the horizontal frames of the floors. The building is built one floor at a time. Once all the walls have been positioned and the attic has been placed, the walls of the upper floor are placed on top of it and so on.

The slab below acts as a platform for the next floor (hence the name Platform Frame)

With this type of construction system our company is able to reach 3/4 floors.

CONSTRUCTION SECTIONS AND THEIR USE

Production and assembly on site

X-LAM Construction System

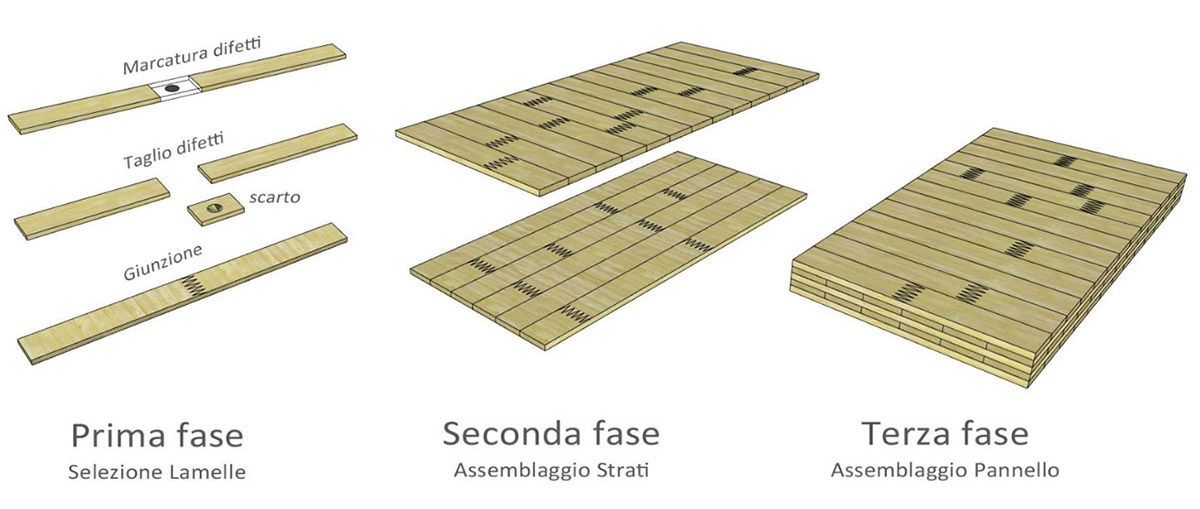

The panels are made at the company with which we collaborate, with numerical control machines that select the individual boards, eliminate defects (knots), create finger joints for joints to form a surface, which will then be overlapped transversally to form a series of stratifications glued one on top of the other.

This alternation of orthogonality also creates, as is easy to imagine, an alternation of arrangement of the fibers and therefore of the resistant direction, giving greater resistance to the entire panel in both directions.

Wood, by its nature, is in fact an anisotropic material, characterized by a different resistance according to the directions: the maximum value occurs in the direction parallel to the fibers, to a much lesser extent if perpendicular or transversal.

XLAM is a product that overcomes these problems, the naturally limited dimensions of the trunks and allows the use of those boards which due to defects and resistance would otherwise be discarded or in any case not intended for structural uses.

It is a technological product suitable for prefabrication. The various walls and floors are cut and shaped to size, to then be transported to the construction site and assembled there. With the help of a crane and a few workers, processing times are reduced to a few days.

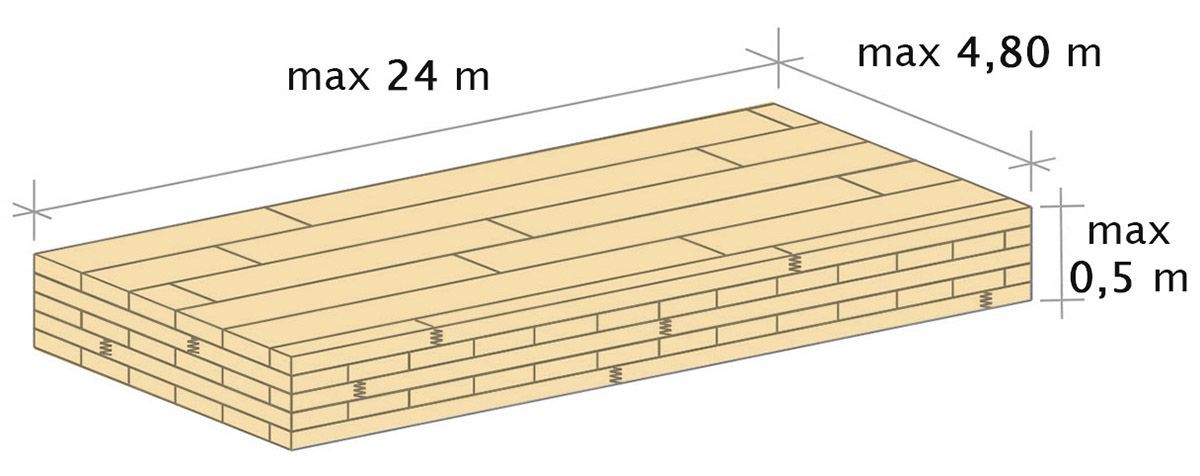

Standard production includes panels which as a rule do not exceed, in the shortest dimension, the height of one building floor, for obvious reasons of design and construction expediency, but also for reasons of transport of the finished panel.

The maximum dimensions of the x-lam panels are related to the size of the means of transport and can reach 24.0 m in one direction, 4.80 m in the other and a thickness of 500 mm.

CONSTRUCTION SECTIONS AND THEIR USE

Their Dimensions:

Anti-seismic performance and fire resistance

It is a certified anti-seismic product. In tests carried out in Japan in 2007, a 7-storey x-lam building, built with red fir from Val di Fiemme, and placed on a shaking table, resisted very well in the simulation of the terrible and destructive Kobe earthquake of 1995, with a magnitude of 7.2 on the Richter scale, which caused the death of over six thousand people.

It is fire resistant. Wood, due to its organic nature, is a combustible material. But the wood carbonization process is very slow, with speeds in the range of 0.55-1.0 mm/min depending on the wood species, density and type of wood-based material or product.

The carbonization of the surface protects the internal layers of the panels so that the structure collapses over a long time. The loss of efficiency of a wooden wall occurs due to a reduction in the resistant section and not due to a decay of the mechanical characteristics (as for steel).

Uncharred wood remains efficient from a mechanical point of view until the section is reduced so much that it can no longer fulfill its load-bearing function. XLAM further improves these parameters